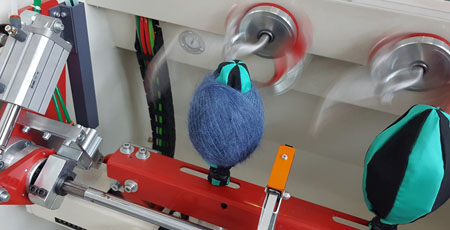

BALL WINDING

BALL WINDINGWinding packages the yarn into a useful, compact form, generally for subsequent retail sale.

Balls of yarn are also some of the most recognizable types of yarn packaging.

Balls are easy to work with and the ends can be pulled from the center or the outside. The spherical shape helps avoid tangles as you're working.

On the market you can find different types of balls: regular balls, donuts, cakes, inner-core balls.

SOME SAMPLES OF THE FINAL PRODUCTS