PIN DRAFTER - GILLING MACHINE

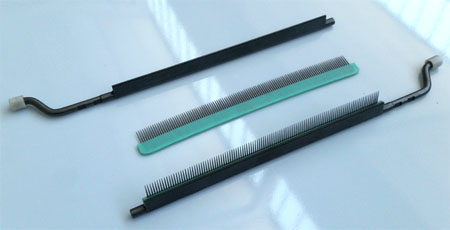

The carder begins the process of aligning the fibers in a parallel arrangement, but pin drafting completes this process.

In addition, drafting blends together different fiber types or colors, creates a uniform sliver to produce an even yarn without thick and thin defects, and can be used to produce a sliver of any desired thickness.

Drafting considerably influences the quality of the final product, as it is the final step in which any sliver irregularities are corrected prior to spinning.

Whereas a drawframe is traditionally used in the straightening and parallelizing of cotton and other short fibers, a gill box pin drafter is used for processing wool, alpaca, and other long staple fibers.

THE RAMELLA DIFFERENCE

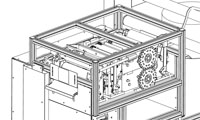

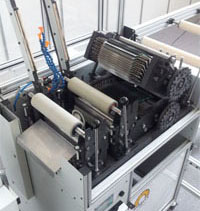

THE RAMELLA DIFFERENCEThe solid structure, attention to detail, and quality at an affordable price make the Ramella gill box drafter the ideal tool to regularize and draft the fibers.

Unlike the second hand pin drafters driven by screw mechanisms the Ramella gill box drafter offers:

• A very high speed.

• Maximum flexibility with the electronic control of the motors.

• Less noise than the screw system.

• Greater economy of operation and maintenance.

Compared to other models on the market the Ramella drafter offers:

• A machine specifically designed for small commercial mills and laboratories.

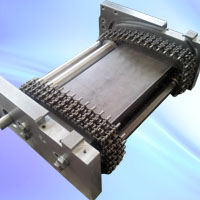

• A low noise, chain driven pin field.

• A driven creel to reduce sliver breakage.

• A solid structure designed to last.

SOME SAMPLES OF THE FINAL PRODUCTS

DEMONSTRATION VIDEO

Loading the player...