SLIVER STORAGE - CAN COILER

SLIVER STORAGE - CAN COILERTo transport and handle the sliver in the best way you need to store it properly without the fibers being damaged and without the sliver regularity is compromised.

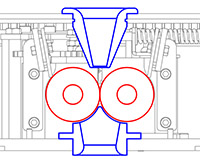

To do this process the textile industry uses a machinery called can coiler.

This machine carries the sliver and deposits it inside of cylindrical cans in a regular way.

In order to preserve the quality of the sliver this operation must be done at the end of each step and then after the carder, after the pin drafter and after the comber.