CARDING

CARDINGThe carding machine is the heart of the spinning mill.

After the scoured fiber has been opened with the picker, the carder disentangles the unorganized tufts and aligns the individual fibers into a parallel arrangement.

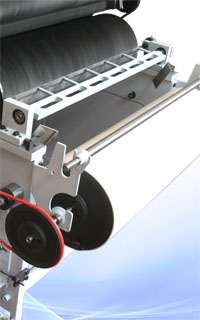

The carder achieves this by passing the fibers between differentially moving cylinders covered with card clothing.

As the fiber moves through the machine, the carding process ejects short fibers and begins blending different fiber types or colors.

THE RAMELLA DIFFERENCE

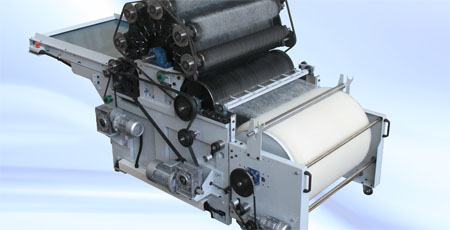

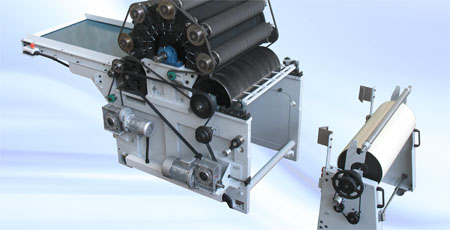

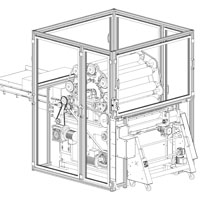

THE RAMELLA DIFFERENCE• An extremely solid and stable structure, made to last.

• The components are machined for maximum precision and quality.

• The cylinders are driven independently by 4 motors with electronic speed control.

• The rigid card clothing is durable and allows quick cleaning after each carding run.

• All cylinders are mounted on sealed ball bearings without bushings.

• A modern design specifically created to meet the needs of small production mills and laboratories.

SOME SAMPLES OF THE FINAL PRODUCTS

DEMONSTRATION VIDEO

Loading the player...